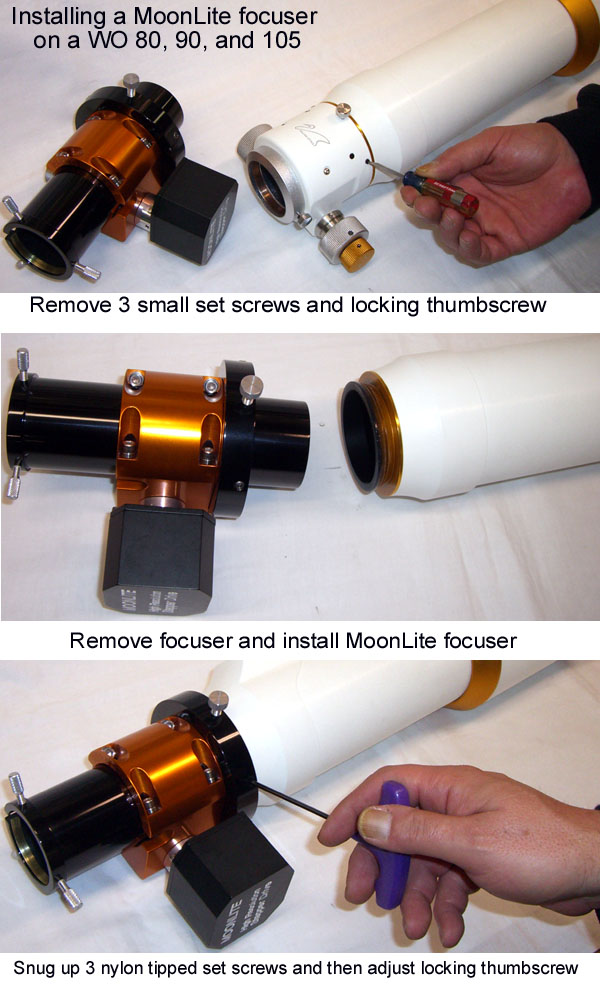

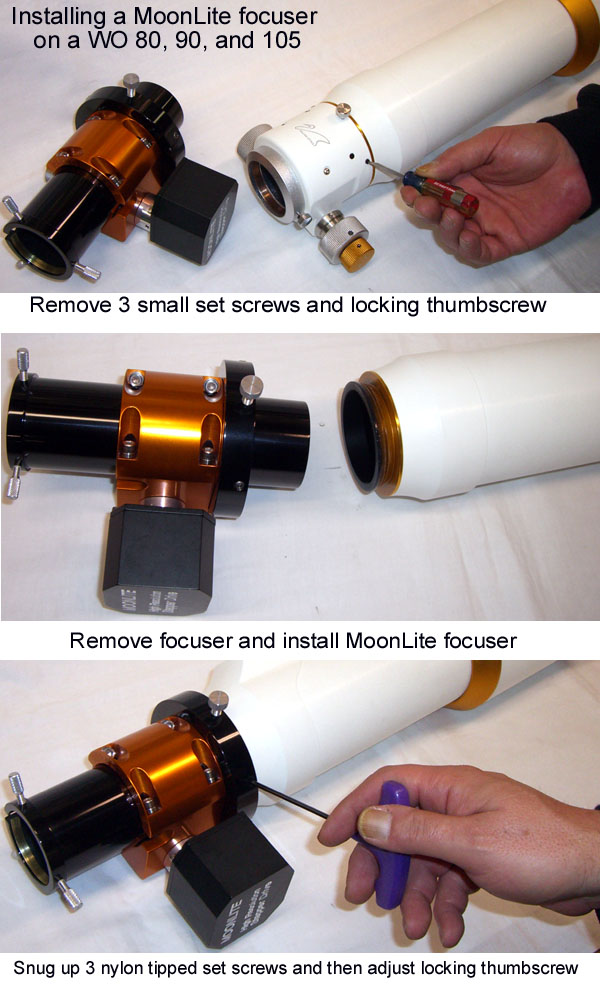

Installing a MoonLite Refractor Focuser

The different size interface adapters are designed to allow the focuser to bolt on to a variety of refractor models simply using the same bolt pattern.

This provides the correct spacing and adds much needed weight on the focuser side of the

telescope. Installation in most cases is just a matter of unbolting the original

focuser and bolting on the new unit.

Collimating the focuser can be achieved by adjusting the three collimating setscrews and three mounting bolts in a push pull configuration, however it is

collimated at time of assembly and should not require any further collimation.

The drawtube pressure can be adjusted to each user's preference. Increasing the

pressure increases the load capacity (vertical lifting capacity) of the focuser.

Decreasing the pressure lowers the load capacity but gives the focuser a smoother

focusing action. We set the focuser at approximately 5 lbs. at time of assembly;

however, you can adjust it to be less or more depending on your specific needs. The

ideal setting is to have it adjusted so the focuser can hold the heaviest load

presented without slipping and requiring no additional force. This will give the

focuser the best feel and still provide the vertical lifting capacity required.

Just turn the black nylon thumbscrew located between the two setscrews on the bottom

of the focuser to adjust to your liking. Or do a course adjustment by turning the 2

set screws a small amount CW located on each side of the fine Nylon thumb screw

adjustment

To maintain the CF focusers performance, keep all bearing and shaft riding surfaces

clean. All Crayford style focusers require a clean bearing to drawtube surface for

smooth operation. The drawtube has been polished to remove all machine marks and

hard anodized resulting in the action having a super smooth feel. Keeping the

surfaces clean will keep the focuser operating at optimal performance.

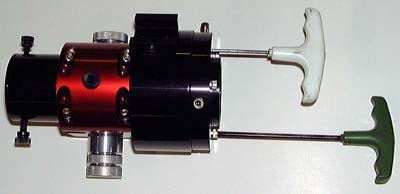

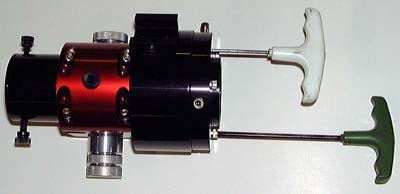

Dual rate focuser owners may want to break in the 8:1 reduction unit by running it

up and down when first receiving the focuser. It is adjusted fairly tight at the

time of assembly and requires a little use to come up to peak performance. No

maintenance should be required on the reduction unit as it is packed with lithium

low temperature grease for the life of its operation.

|